Second the curb should be available in a variety of heights depending upon geographical location and be available with pitch factory built into the curb since most roofs are sloped for drainage in some manner.

Roof curb leveling.

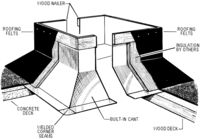

Specify prefab roof curbs for use with all roof penetrations and roof mounted equipment including and not limited to hvac units duct openings pipe penetrations power roof exhauster intake and relief vents flues or job fabricated items.

Full service curb manufacturers offer this type of diversification and coordination with a given roof system by offering curbs which are canted non canted raised canted self flashing or designed and manufactured to match the exact profile of a pre engineered metal roof system.

2p style self leveling curbs for hvac units.

Normally that temperature will only be 3 to 4 degrees different than outside when the equipment has been running.

More testing using the same test hole you can measure the air temperature within the cavity of the curb.

Along the top surface of the curb where the vir will be sitting place the supplied1 16 thick by 1 wide neoprene foam tape.

2 style self leveling curbs for pitched roofs.

Testing drill a small access hole at the top of the curb below the flashing so water won t enter the curb preserving the integrity of the roofing membrane.

Specify prefabricated roof curbs and related products by a roof curb manufacturer not with or by the equipment manufacturer.

1 2 and 5 style sound curbs.

Then measure the pressure in the cavity of the curb.

4 style heavy duty ahu roof curbs.

Make sure that all four sides of the sheet metal roof curb are level before assembling the vir to the roof curb.